Battleship Texas Restoration

Preserving History, Engineering the Future

The Project

The Battleship Texas is a symbol of American naval history, recognized for its groundbreaking advancements in warfare technology and distinguished service in both World Wars. From 2019 to 2024, Valkor Energy Services (VES) played a central role in managing the ship’s restoration — ensuring this iconic vessel is preserved for future generations.

Project Value

Vendors & Contractors Coordinated

Restoration Effort

Gallons of Foam Installed/Removed

Tons of New Steel Replaced

Man-hours in Shipyard without Lost Time Incident

From concept to completion: a five-year journey redefining maritime restoration (2019–2025)

VES led the most complex ship relocation and restoration ever executed in Texas — a five-year mission that combined engineering, logistics, and risk management excellence to preserve a national treasure.

Scroll through the story of how VES became the only firm to secure insurance, permits, and execution clearance to move the Battleship Texas.

Feasibility & Proof of Possibility

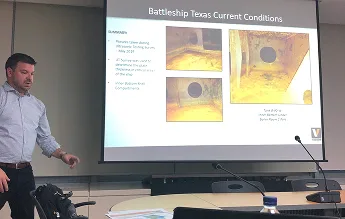

Challenge

A 105 year old Battleship Texas was leaking about 2,500 gallons of water per minute and needed critical repairs and dry docking to extend the life of the historic monument.

VES Action

- Contracted by the Battleship Texas Foundation (BTF) to conduct a full feasibility study.

- Delivered technical and risk assessments proving the project could be executed safely.

- Testified to the Texas Legislature to secure restoration funding.

- Created a comprehensive execution plan, including cost, logistics, and preliminary tow strategy.

Milestone Achieved

Texas State Legislature approve project funding based on VES feasibility study report and testimony.

Project recognized as technically feasible and insurable — a first for a vessel of this age and scale.

Engineering, Permits & Insurance

Challenge

Convince regulators and insurers that towing a 108-year-old, 30,000-long ton battleship through the Houston Ship Channel — one of the busiest waterways in the U.S. — was possible and safe.

VES Action

- Coordinated with U.S. Coast Guard, Houston Pilots, Galveston Pilots, and underwriters to design a zero-failure tow plan.

- Created detailed hydrostatic and stability models, foam calculations, and contingency scenarios (Plan A, B, and C).

- Installed 750,000 gallons of closed-cell polyurethane foam for buoyancy and watertight integrity.

- Managed operations during the COVID-19 pandemic, ensuring continuous progress under restrictions.

Milestone Achieved

VES becomes the only company to obtain insurance and permit approval for the operation.

USCG issues formal clearance to execute full-channel tow.

Tow plan recognized by multiple maritime authorities as an unprecedented engineering feat.

The Tow: Houston to Galveston

Challenge

A one-day, high-stakes tow requiring absolute precision – closing sections of the Houston Ship Channel, coordinating dozens of marine assets, and safely managing a highly publicized event.

VES Action

Directed real-time coordination between tug operators, pilots, USCG, and BTF.

Managed communications and command center logistics for continuous updates.

Oversaw all safety operations, emergency contingencies, and insurance compliance in motion.

In charge of a riding crew consisting of pilots, USCG, SERT, naval architects, salvage team, divers, tug operators, and BTF crew members.

Milestone Achieved

Historic 34-nautical mile tow executed flawlessly, incident-free, on schedule.

Successful dry docking of 108 year old vessel for the first time in 34 years.

VES earns commendations from USCG and state officials for operational excellence.

Dry Dock & Structural Rehabilitation

Challenge

Once docked, decades of corrosion and post-war-era modifications revealed structural damage far beyond expectations.

VES Action

Identified and secured a 30-foot-draft dry dock, which was capable to lift the Battleship Texas, for Gulf Copper Shipyard in Galveston, TX.

Removed foam and began 18 months of steel restoration and blister tank reconstruction.

Replaced 700 tons of steel at and below the waterline.

Supervised 100+ personnel daily across multiple trades under a time-and-materials contract.

Developed new construction methodologies for riveted, century-old steel.

Milestone Achieved

Hull watertight integrity fully restored.

Refloat completed March 5, 2024 — precisely as scheduled.

No lost-time incidents in 18 months of heavy industrial work.

Superstructure & Historical Preservation

Challenge

Restore authenticity while meeting modern safety standards — working within budget and time constraints.

VES Action

Directed gun platform and superstructure repairs.

Oversaw Foretop removal, restoration, and reinstall.

Managed full repainting of hull and topside structures.

Began wood deck restoration campaign, including subdeck repairs.

Coordinated historical compliance with Texas Historical Commission and preservation experts.

Milestone Achieved

Exterior and structural preservation completed to museum-grade standards.

Historic profile of Battleship Texas fully re-established.

Resilience & Legacy

Challenge

Complete final works under active Gulf storm conditions — while preparing the ship for public return.

VES Action

Designed and implemented hurricane mooring strategy to secure the vessel during Category 1 Hurricane Beryl.

Oversaw final cosmetic works, interior refurbishments, and system upgrades.

Continued collaboration with BTF on educational access and long-term preservation.

Initiated and managed engineering design for infrastructure and mooring for the final destination location.

Milestone Achieved

Battleship Texas survives hurricane season undamaged under VES mooring design.

Public reintroduction phase begins in 2026.

VES’s leadership turned a deteriorating warship into a symbol of technical and managerial excellence.

Through engineering creativity, vendor coordination, and real-time decision-making, VES redefined what’s possible in maritime restoration.

Impact Summary:

$60M restoration effort

5-year execution timeline

100+ vendors coordinated daily

Only insured and permitted firm for the operation

Zero major incidents throughout the project

Preserving history and solving complexity — VES delivers where others hesitate.

Continuing the Mission

VES is proud to have helped safeguard the Battleship Texas. The restoration and educational programs continue — join us in helping conserve history.

After decades of exposure, the vessel required one of the most complex preservation efforts in U.S. naval history.

Historical Significance

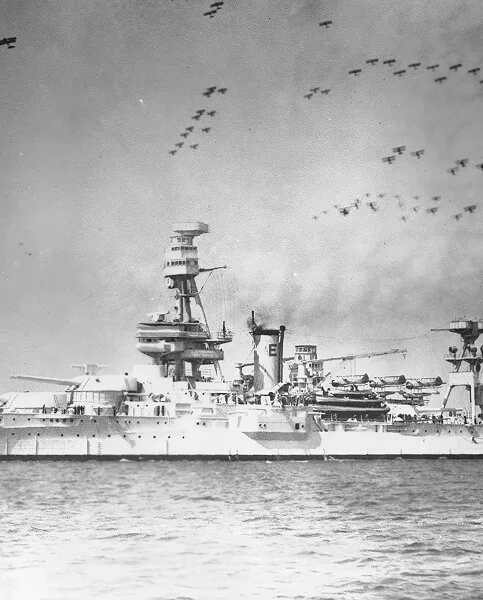

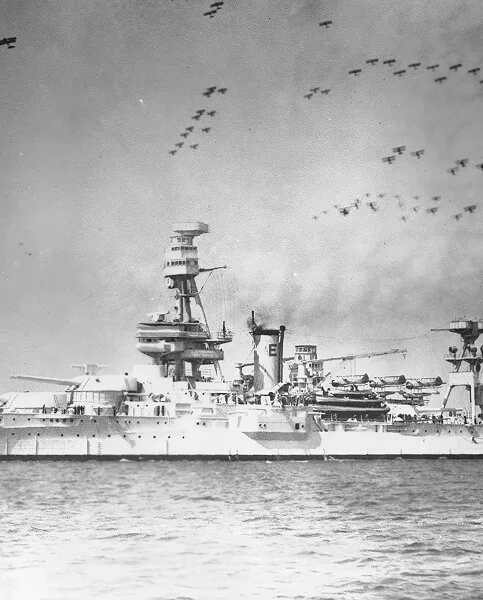

Commissioned in 1914, USS Texas (BB-35) made history as:

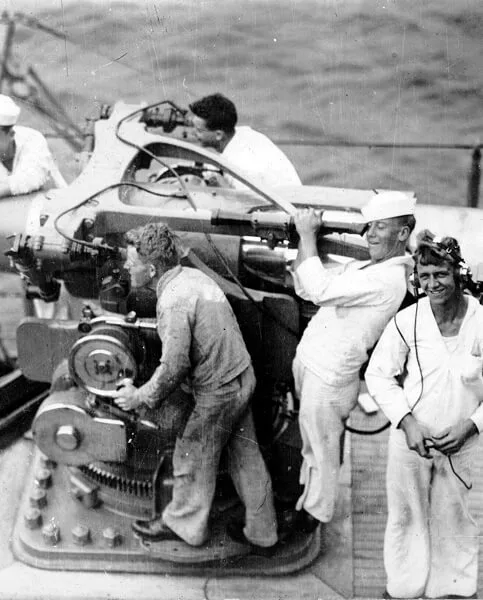

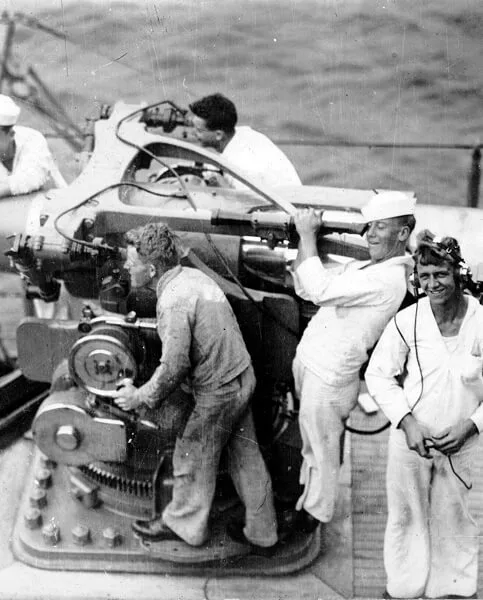

The first battleship outfitted with anti-aircraft guns

The first battleship to launch an aircraft from its deck

A decorated warship in both WWI (North Sea patrols) and WWII (D-Day, Iwo Jima, Okinawa)

After decades of exposure, the vessel required one of the most complex preservation efforts in U.S. naval history.

Historical Significance

Commissioned in 1914, USS Texas (BB-35) made history as:

The first battleship outfitted with anti-aircraft guns

After decades of exposure, the vessel required one of the most complex preservation efforts in U.S. naval history.

VES Role in the Restoration

VES provided total Project Management including strategic leadership, vendor coordination, and on-site supervision from feasibility studies and legislative testimony to daily management of 100+ personnel in dry dock.

Key Responsibilities

VES leads complex maritime projects from planning to execution, overseeing funding, logistics, structural restoration, and risk management to ensure safety, efficiency, and exceptional results.

Securing Project Funding

Contracted by the BTF for feasibility studies and legislative testimony to secure state funding

Tow Plan Development

Development of vessel preparation and insurable tow plan through the Houston Ship Channel

Shipyard & Dry Docking

Selection of shipyard partner including dry dock acquisition in Galveston

Hull Repairs Oversight

Supervised hull repairs: 700 tons of steel replaced, blister tanks rebuilt, hull repainted

Deck & Structure Restoration

Managed wood deck restoration campaign and superstructure repairs

Hurricane Mooring Strategy

Oversaw hurricane mooring strategy during Category 1 Hurricane Beryl

Restoring History Together: The Battleship Texas Project

Gallery

Preserving history and solving complexity

VES delivers where it matters most.

Preserving history and solving complexity